How to Sharpen Dental Instruments?

Here are the main steps to sharpen dental instruments:

- Select specialized sharpening tools like sharpening stones or diamond sharpeners suitable for the specific dental instrument.

- Carefully inspect the instrument for damage, wear, or dullness, focusing on cutting edges and visible nicks or burrs.

- Secure the instrument firmly to prevent movement during sharpening.

- Maintain the appropriate angle and pressure while sharpening, ensuring consistent, even pressure for desired sharpness.

- Periodically test sharpness during sharpening dental instruments by running a fingernail or gloved finger along the cutting edge.

How Often Do Dental Instruments Need to Be Sharpened?

According to dental professionals and guidelines, dental tool sharpening once a week is recommended to ensure their effectiveness during procedures.

What Is The Best Stone to Sharpen Dental Hygiene Instruments?

Ceramic and Arkansas stones are the best options for sharpening dental hygiene instruments due to their consistency, durability, and compatibility with stainless steel instruments.

What Is Used to Sharpen Periodontal Instruments Manually?

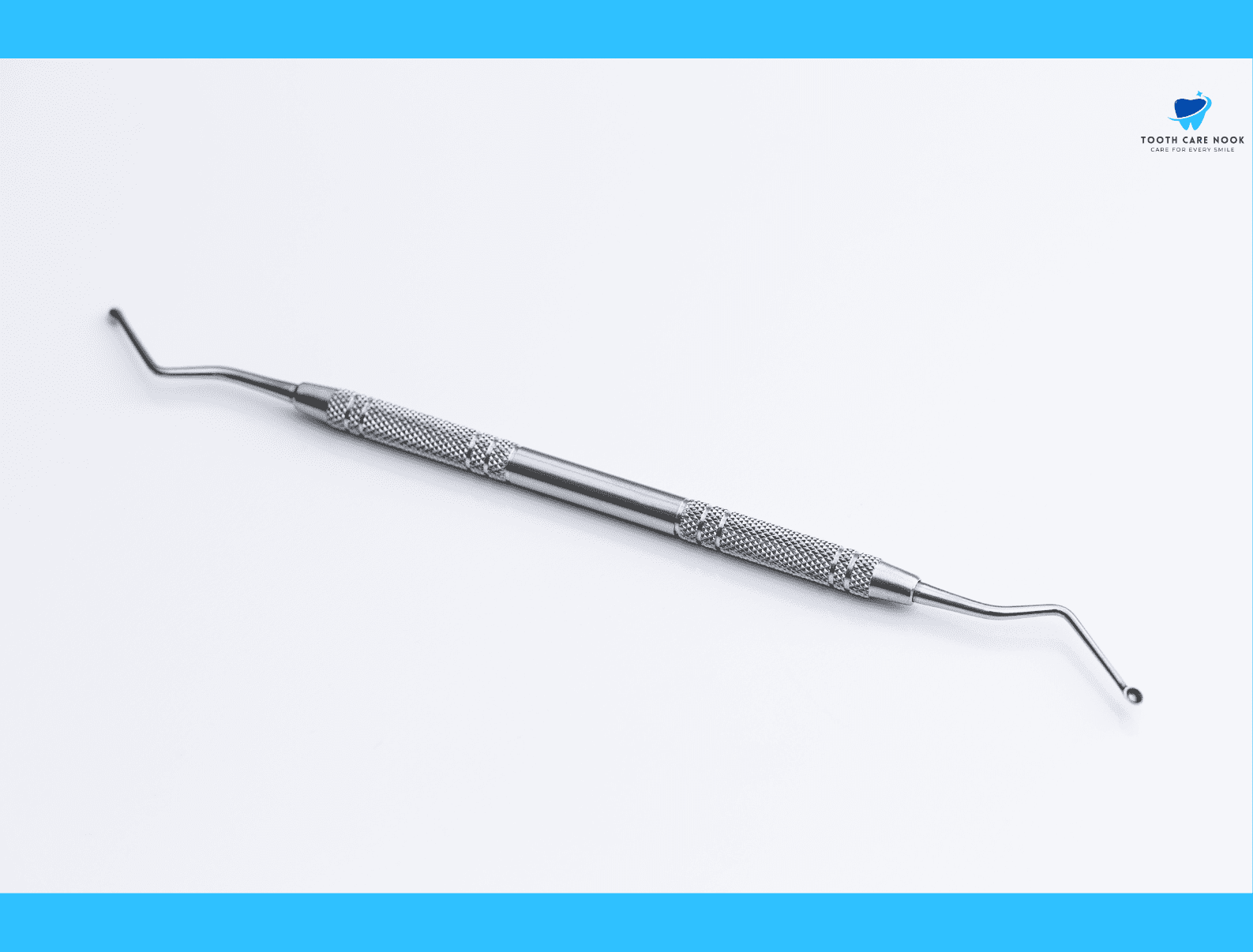

Periodontal instruments are manually sharpened using sharpening stones or files specifically designed for dental instruments. These tools are essential for maintaining the sharpness and effectiveness of periodontal instruments. The instruments include scalers, curettes, probes, and explorers.

How to Sharpen Dental Scalers?

Here’s a step-by-step process to sharpen dental scalers:

I: Inspect the Scaler:

Choose a sharpening stone or file specifically designed for dental instruments. Diamond-coated or ceramic stones are commonly used for sharpening dental scalers.

Before sharpening, carefully inspect the scaler for any visible signs of dullness, damage, or wear on the cutting edges. Pay attention to any nicks, burrs, or irregularities that may affect the instrument’s performance.

ii: Identify the Bevel Angle:

Determine the bevel angle of the scaler’s cutting edges. Most scalers have a single bevel, but some may have double bevels. Understanding the bevel angle is a must for achieving the correct sharpening angle.

Hold the stone or file at the appropriate angle relative to the scaler’s cutting edge. The sharpening angle typically ranges from 100 to 110 degrees which depends on the scaler’s design.

iii: Apply Lubrication:

Some dental professionals prefer to apply a small amount of water or lubricant to the sharpening stone or scaler’s cutting edge to facilitate smoother dental sharpening. This helps to prevent overheating and ensures consistent sharpening of dental instrument results.

iv: Sharpen the Cutting Edge:

With a steady hand and consistent pressure, move the sharpening tool along the entire length of the scaler’s cutting edge in a sweeping motion. Maintain the bevel angle throughout the sharpening process to achieve a uniform edge.

Periodically check the sharpness of the scaler’s cutting edge during sharpening by gently running a fingernail or gloved finger along the edge. A sharp scaler should produce a smooth, sharp edge without any resistance.

How Sharpening Gracey Curettes Is Done?

Here’s the process of sharpening gracey curettes:

Inspect the Curette:

Carefully examine the curette for any signs of dullness, damage, or wear on the cutting edges. Inspect both the face and the lateral surfaces of the curette’s working end for any irregularities.

Secure the Curette:

Secure the Gracey curette firmly in place using a stable surface or instrument holder to prevent any movement during the sharpening dental instruments process. This ensures safety and stability during the process.

Identify the Bevel Angle:

Determine the bevel angle of the curette’s cutting edges. Gracey curettes typically have a single bevel, and the recommended sharpening angle is approximately 70 to 80 degrees.

Periodically check the sharpness of the curette’s cutting edge during sharpening by gently running a fingernail or gloved finger along the edge. A sharp curette should produce a smooth, sharp edge without any resistance.

Clean and Sterilize:

After sharpening dental instruments, thoroughly clean the Gracey curette to remove any sharpening debris or residue. Sterilize the curette according to standard infection control protocols before using it in patient care.

How to Sharpen Dental Elevators?

Here’s the procedure to sharpen dental elevators:

Inspect and Secure the Elevator:

Before sharpening, carefully examine the elevator for any signs of dullness, damage, or wear on the cutting edges. Inspect both the working end and the shank of the elevator for any irregularities.

Secure the dental elevator firmly in place using a stable surface or instrument holder to prevent any movement during the sharpening process. Stability is essential for safety and precision during sharpening.

Identify the Bevel Angle:

Determine the bevel angle of the elevator’s cutting edges. Most elevators have a single bevel, and the recommended sharpening angle is typically around 40 to 45 degrees.

Sharpen the Cutting Edge:

With steady pressure and a controlled motion, move the sharpening stone along the entire length of the elevator’s cutting edge in a sweeping motion. Ensure that the entire cutting edge is evenly sharpened.